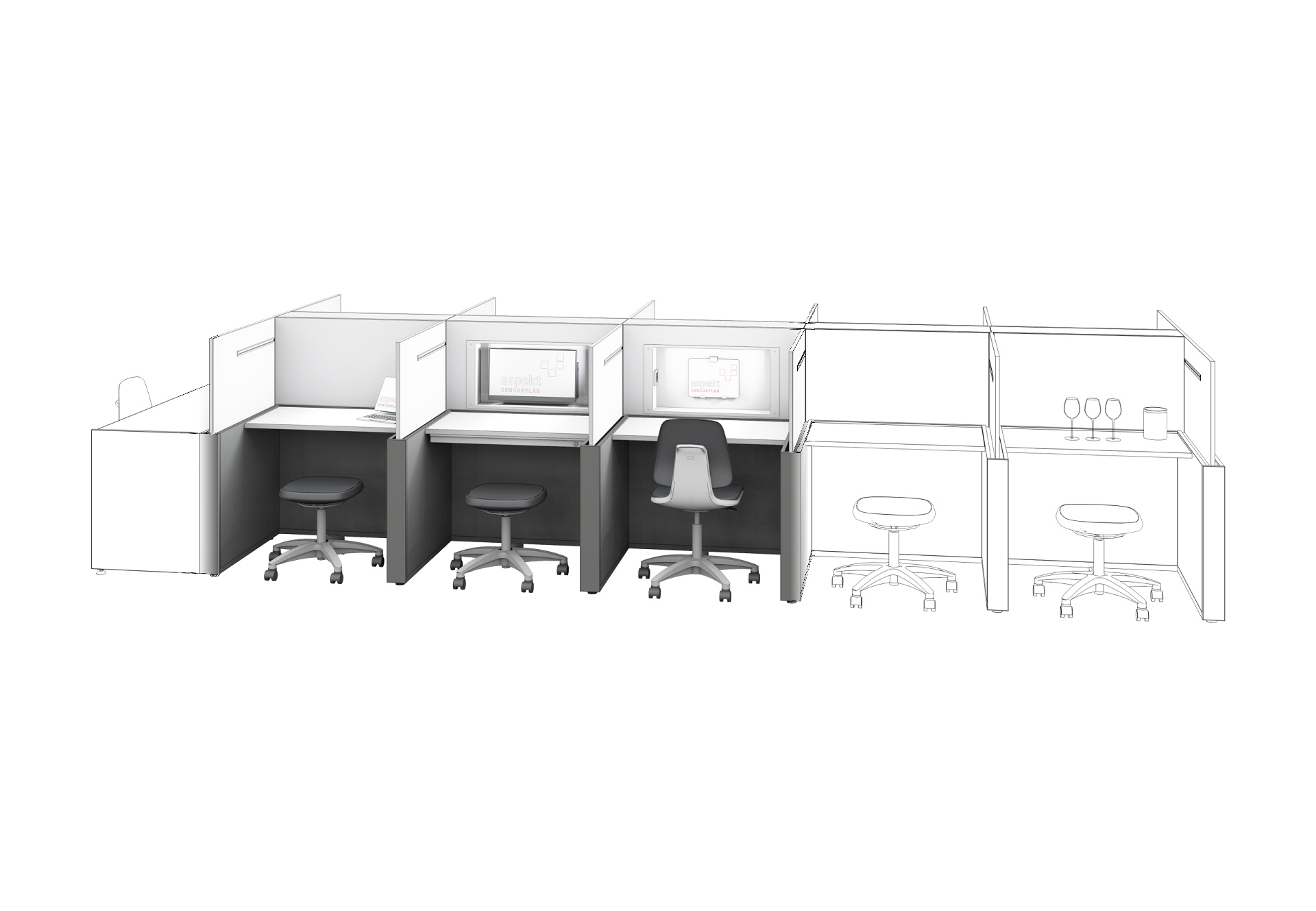

Fixed-Sensory-Table (FST-E)

Sensory table

for group work, discussion, training & sensory analysis

in a room from 20 m²

Optional space for panel line with control of the electrically raised and lowered privacy screens

Work surface in various versions with utensil or keyboard drawer

Alcove with monitor, client PC and network connection

Niche with removable holder for tablet PCs and charging option

Can be extended as required in increments of 2 from 6 seats upwards

The FST-E sensor desk can be positioned in a central location in the company in a resource-saving manner with standard infrastructure such as room darkening, power supply and network connection in many room layouts. Screen walls can be raised from the inside of the table using an electric motor in around 30 seconds. Further options such as test station lighting and integration of hardware for questionnaire software such as "Fizz" or "Compusense" are available. The versatility of the space increases the visibility and importance of sensor technology in the company.

All test areas are available with test station lighting. It is possible to switch between warm and cool white (with a very high color rendering index), as well as red, green or blue light (RGB), mix, dim and save. The lighting scenes are called up using programmed buttons or an app.

Article for the trade journal QM! - Tasting table for sensory analysis.

Project example Offenbach (Germany)

Visualisierung

Procedure

- Planning and non-binding offer

Demand:- Planning of a sensory laboratory with preparation room (daylight) and a room for group work and sensory analyses

(panel room without daylight), separated by a light-tight and noise-reducing sliding door partition wall - Compliance with DIN EN ISO 8589 with test station lighting

- The customer's product range does not require sample preparation such as heating, frying, etc.

- Interface specification for cooling ceiling, network, power supply, sanitary, ventilation (TGA planning)

- Choice of decor for the base and plinth area of the tasting table, partition wall and kitchen to match the floor covering

Potential:

- Niches for the use of tablet PCs for the questionnaire software (FIZZ)

- Areas for free-standing appliances in the preparation area

- Sideboard in the test room with synchronized lighting to present the product range

- Number of test stations can be expanded or reduced in the event of an internal company relocation

Room:

- 16 m² preparation kitchen

- 40 m² test room

- Planning of a sensory laboratory with preparation room (daylight) and a room for group work and sensory analyses

- Commissioning, production release & production

- On-site installation with acceptance and handover (2.5 days & 3 people)

Realization

Project example Laufen (Switzerland)

Visualization

Procedure

- Planning and non-binding offer

Demand:- Planning of the tasting room with panel line, storage capacity, sample provision

and optional test stations in a very small area - Compliance with DIN EN ISO 8589 with test station lighting

- Sample preparation in neighboring room, use of shelf trolleys with trays

- Interface specification for network and power supply (TGA planning)

- Choice of decor for the base and plinth area to match the corporate identity

Potential:

- Niches for the use of tablet PCs for questionnaire software (SensoTASTE)

- Room acoustic measures (acoustic elements)

- Sideboard in the test room with synchronized lighting to present the product range

- Number of test stations can be expanded in a different room context

Room:

- 23 m²

- Planning of the tasting room with panel line, storage capacity, sample provision

- Commissioning, production release & production

- On-site installation with acceptance and handover (2.5 days & 3 people)

Realization

Zagreb (Croatia)

Visualization

Procedure

- Planning and non-binding offer

Demand:- Meeting and tasting room with adjoining preparation kitchen

- Compliance with DIN EN ISO 8589 with test station lighting

- Sample preparation in neighboring room, use of shelf trolleys with trays

- Interface specification for network and power supply (TGA planning)

- Choice of decor for the foot and plinth area to match the floor covering

Potential:

- Number of test stations can be expanded in a different room context

- Room acoustic measures (acoustic elements)

Room:

- 25 m²

- Commissioning, production approval & production, delivery in advance by forwarding agent

- On-site installation with acceptance and handover (1 day & 1 person)